I have owned multiple vehicles that were manufactured before 1962. I enjoyed working on these trucks, sitting on the wheel well, valve cover set aside, adjusting the valves on the engine while it ran and clattered beneath you. This process usually involved a few choice beverages and a tool wrangler/flashlight holder/moral support team (my son and/or daughter). Now you need special tools just to view the engine beneath all of the plastic covers. The days of simple automotive diagnostics are gone. There was a time when you could troubleshoot a good portion of your automotive issues with a set of wrenches and a vacuum gauge. Those days are gone. Sadly, I don’t even own an engine (that doesn’t cut grass) that has a carburetor any more. Both of my motorcycles require scan tools for any advanced engine diagnostics and newer automobiles require scan tools with frighteningly high price tags. You can get simple scan tools that plug into your DLC port and allow you to read DTC’s (Diagnostic Trouble Codes) on your phone. But to troubleshoot complicated issues, you need a professional tool and access to professional information. Today a mechanic is a technician with mechanical, electrical, HVAC and IT skills. More than just a wrencher.

Information of the Highway

There was a time when you could troubleshoot a good portion of your automotive issues with a set of wrenches and a vacuum gauge.

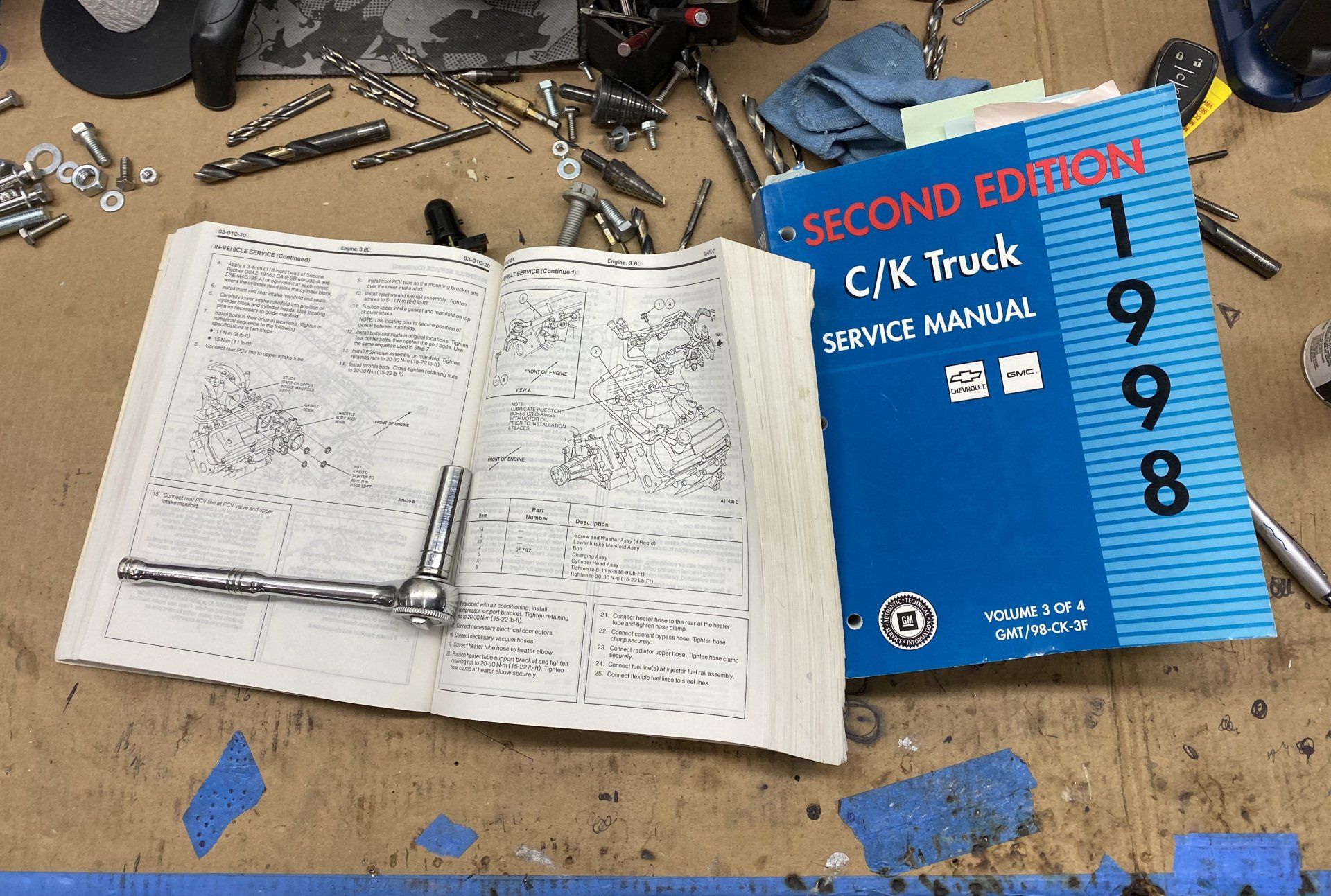

As you advance in your studies of vehicles and of the repair processes, you will begin to discover the usefulness of advanced scan tools and manufacturer information. Automotive repair today is awash in a sea of information, and a lot of this information is of utmost importance to properly repair a vehicle to factory specifications. The days of the Chilton’s Auto Repair Manual are gone. No longer is there ONE piece of information to answer all of your questions. I still keep my old Chilton’s Manuals. 1500+ pages of information on every vehicle at your fingertips. Of course, that vehicle has to be at least 55 years old (you never know when that ’60’s Falcon is going to drop into your lap). The Chilton’s/Haynes manuals are still available, but they are vehicle specific these days and don’t really cover the newest models. These are great choices for the shade-tree mechanic wishing to get his hands dirty and save some money. YouTube also has a wealth of information at your fingertips (this is where I learned that my Royal Enfield has two drain plugs for the oil) and watching someone actually do the task you are wishing to do is immeasurably helpful. Engines were simple air pumping machines in the past. They still are, but no longer are they simple and no longer can one piece of information apply to all. Watch a video on giving an engine a tune up from 1942 and that information literally applies to every engine manufactured in a multi-year span. Pretty basic stuff, but diving deeper into an engine that is increasingly controlled by a computer, your information gets more manufacturer specific. Chilton’s/Haynes manuals just don’t go deep enough for some issues.

To narrow down your options on what you need in your modern shop, there are several resources you can use. For OEM (Original Equipment Manufacturer) one of the best is the NASTF website. The National Automotive Service Task Force offers a huge array or information for OE (original equipment) support. NASTF does not sell anything or offer specific repair information, rather they are a resource to find links to manufacturer websites and services. The information that they offer is free of charge and can connect you with links for specific manufacturers’ services and support and how to subscribe to or join manufacturer programs. NASTF also lobbies on behalf of the independent shop owners. They are a force for weekend technicians and small shop owners nationwide.

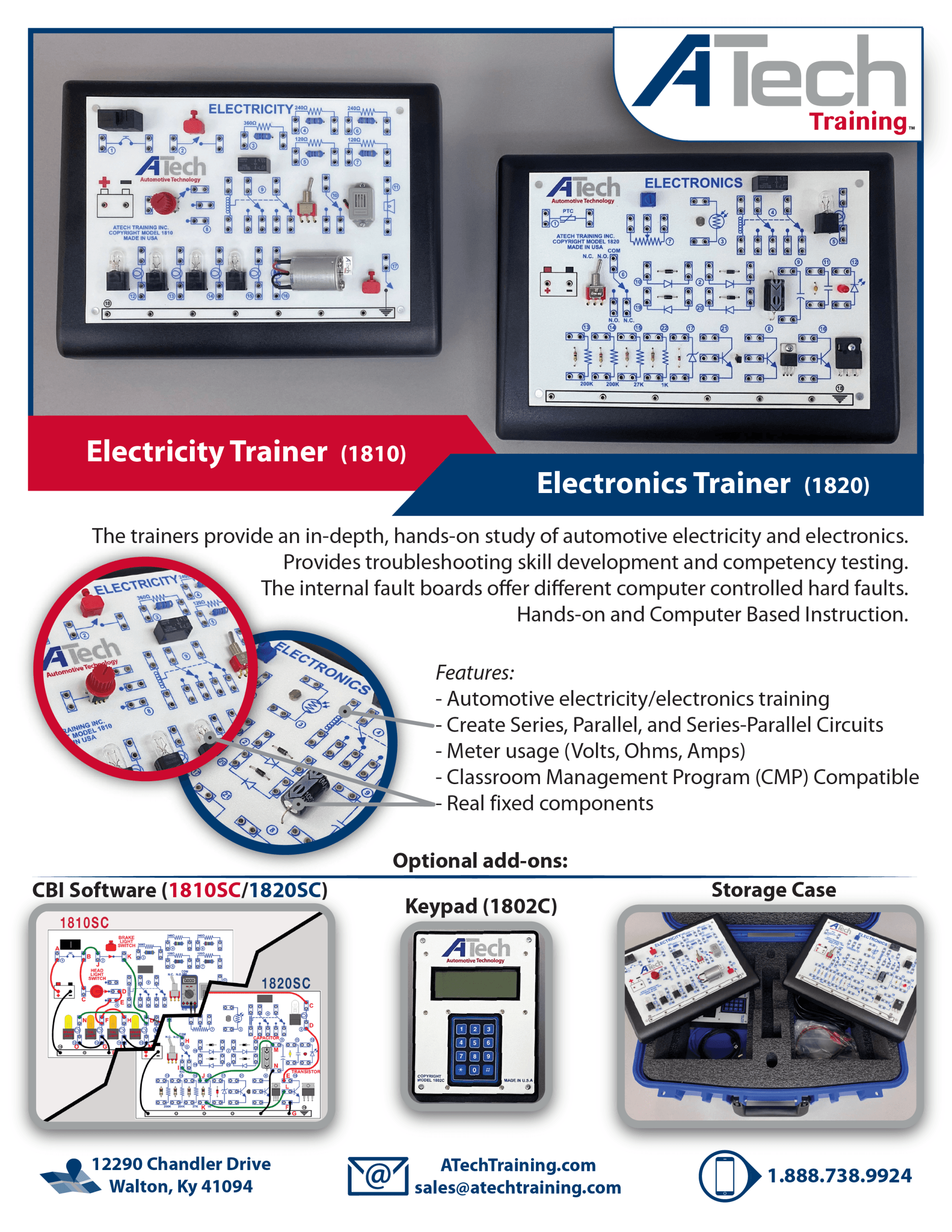

Along with NASTF there are a number of other free online resources to keep the modern technician up to date. These include Engine Professional magazine, Motor Magazine, Auto Service Professional magazine and AA1car.com to name just a few. These offer a number of articles every month along with advice, tips and general information, and all of it is free. Online magazines might not be as good as what you can learn in the classroom or hands on, but most are free and they do contain a wealth of information. And please do not forget the sheer volume of videos that you can find on You Tube. A good portion of these can be hard to watch, but every once in a while you will get some guy in India working on exactly your problem on a Royal Enfield motorcycle just like yours.

On a side note: If you get a chance, watch this short WWII video on automotive troubleshooting from 1942. It’s simple information that applied to every engine in 1942. It’s just the thing I wish I had available when I was a kid and demonstrates how to properly use your vacuum and compression gauges. Thank you for reading and keep the wrenches off the floor.

- Jeff Bogue

NACAT 2022 : August 8th - 11th

2022 NACAT Annual Conference & Expo

Registration and additional information will be available in early 2022.

Hotel information is available from the Cincinnati Marriott RiverCenter. Call (859) 261-2900