What's Old Is New...

As Powertrain Control Modules “PCM” became more powerful and faster, VVT “Variable Valve Timing” which alters the timing of valve lift events, was the predominant feature for both power and fuel economy. This held true until the early 2000’s when Diamler introduced ACC “Active Cylinder Control”, Honda introduced VCM “Variable Cylinder Management”, and GM introduce AFM “Active Fuel Management” cylinder deactivation systems. These systems switched off half of the cylinders during low load activity and they worked fairly well. The technology had finally caught up with the desire for better fuel economy and lower emissions. This natural progression continued until it reached the Dynamic Fuel Management or DFM that was available in the 2019 Chevrolet Silverado 5.3L and 6.2L V-8 engines. Jordan Lee, GM’s Small Block Chief Engineer, stated that “Dynamic Fuel Management enables only the cylinders needed to deliver the power that you want, delivering the best balance of power and fuel economy”. Compared to the old “Active Fuel Management”, which alternated between eight- and four-cylinder operation, the newer “Dynamic Fuel Management” featured 17 different cylinder operation patterns. This greater diversity mixes cylinder patterns constantly to optimize efficiency and power delivery at all speeds. During testing, the 2019 Silverado with the 5.3L engine operated with fewer than eight cylinders more than 60% of the time, increasing fuel economy by roughly 10% and decreasing emissions.

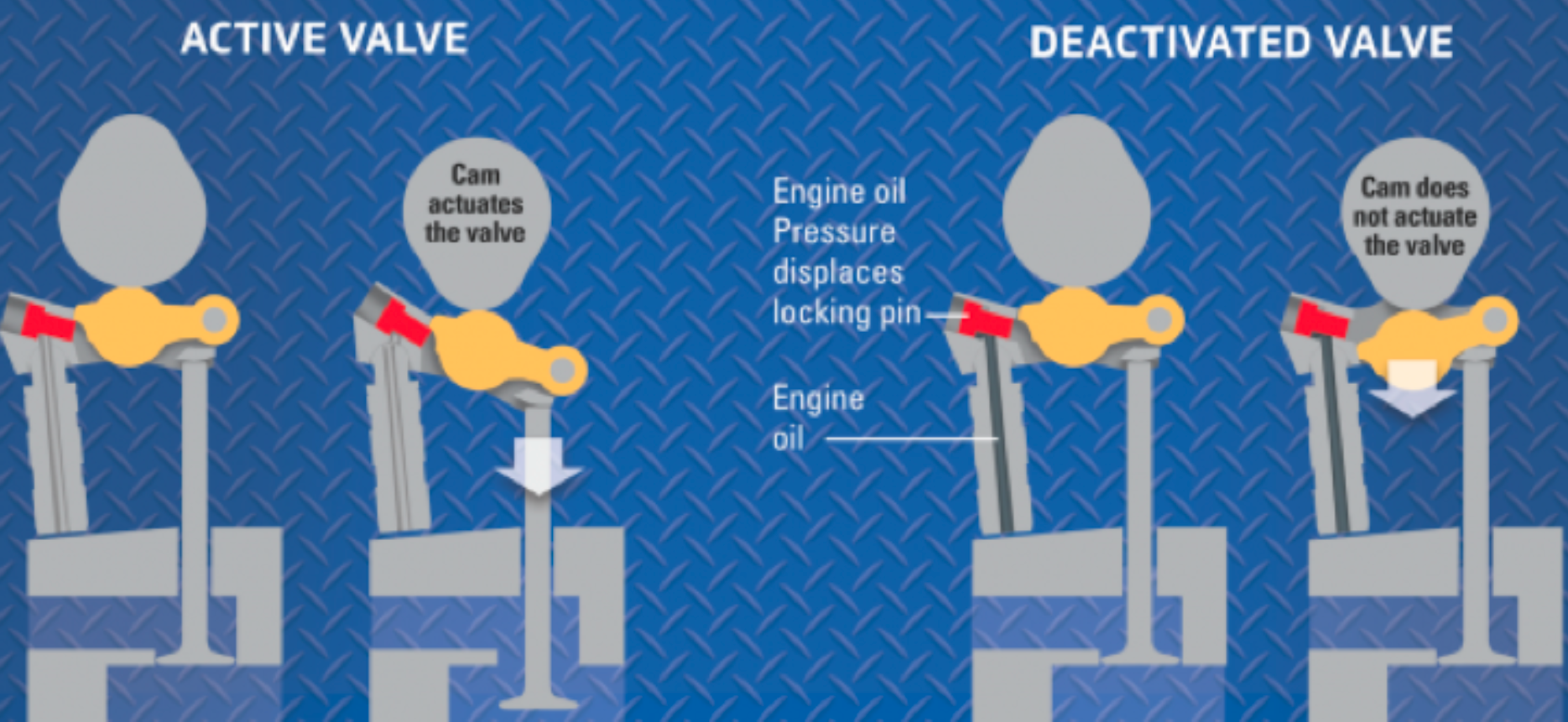

The new DFM is powered by a sophisticated controller that continuously monitors the throttle position and runs a sequence of calculations to determine how many cylinders are required to meet the drivers requested torque needs. It can make these determinations 80 times per second. As it is being monitored, an electromechanical system deactivates and reactivates all 16 of the engines hydraulic valve lifters, controlling valve actuation. The system uses solenoids to deliver oil pressure to control poets in each of the lifters, which then activates or deactivates the lifters’ latching mechanism. When a cylinder is deactivated, the lifter no longer pushes the valve and prevents it from opening. When the cylinder is reactivated, solenoids send an oil pressure “signal” to the control port on the lifter and a latching pin allowing the normal function of opening and closing to resume.

Being that the DFM has complete control of all eight cylinders, 17 different cylinder patterns to maximize power and torque, the engines are technological beasts. Mounting them to eight- and ten-speed transmissions to further enhance the ability to maintain an RPM in the middle of the power band just seems like overkill. Seriously, this is a great engine in a great vehicle, and I just love technology.

View all Products

Request a Quote

ATech is committed to providing world class instructional equipment and materials to enhance and improve automotive technical education. Check out our new YouTube video and learn how our trainers are made, the type of trainers we produce and how our passionate employees work everyday to improve the automotive education for future generations.

Trade Shows and Conferences

During the upcoming months ATech Training has multiple events coming up!

November

11/01/24: Utah Auto Tech, Weber State University Davis Campus, Layton, UT

11/04/24 - 11/10/24: AAPEX SEMA, Las Vegas Convention Center, Las Vegas, NV

December

12/04/24 - 12/07/24: ACTE's CareerTech Vision: Henry B. Gonzalez Convention Center, San Antonio, TX

12/04/24 - 12/07/24: Texas Auto Dealers Competition, Texas Motor Speedway, Fort Worth, TX

ASE Webinar

November 12th, 2024: Exploring Essential Alignment Angles

Join ATech Training for an in-depth webinar covering the purpose and impact of various alignment angles on tire wear, vehicle handling, and steering. Up your undercar skills with Tony Salas as he utilizes ATech Training’s 500E to explain all your alignment angle questions.

December 10th, 2024:

Pull-Up Resistors: Understanding and Teaching Sensor Signals

Join ATech Training for an in-depth webinar covering the function of pull-up resistors in digital circuits and how they are applied in simple applications. Enhance your drivability troubleshooting skills with Tony Salas as he provides a detailed explanation of digital sensor operation using ATech’s state-of-the-art training equipment.

For more information visit the ASE Website!

***Make Sure you receive a confirmation email from ATech Training before scheduling travel***

Upcoming In-House Training Dates

December 10th &11th, 2024

***Must complete pre-training survey to reserve time slot***

View 2024 Product Catalog

Lab Highlight

Arizona Western College instructor Michael Murphy has designed a great lab to help his students thrive in their Automotive Technology program. Their lab is made up of electrical and automotive trainers, car clips, and real vehicles, following ATech's simple to complex learning strategy. In which you start with basic ideas and build on them as the students advance in their education program.

If interested in any of our training or products, please contact us!

If you would like ATech Training to highlight your lab on social media or in our next newsletter contact us.