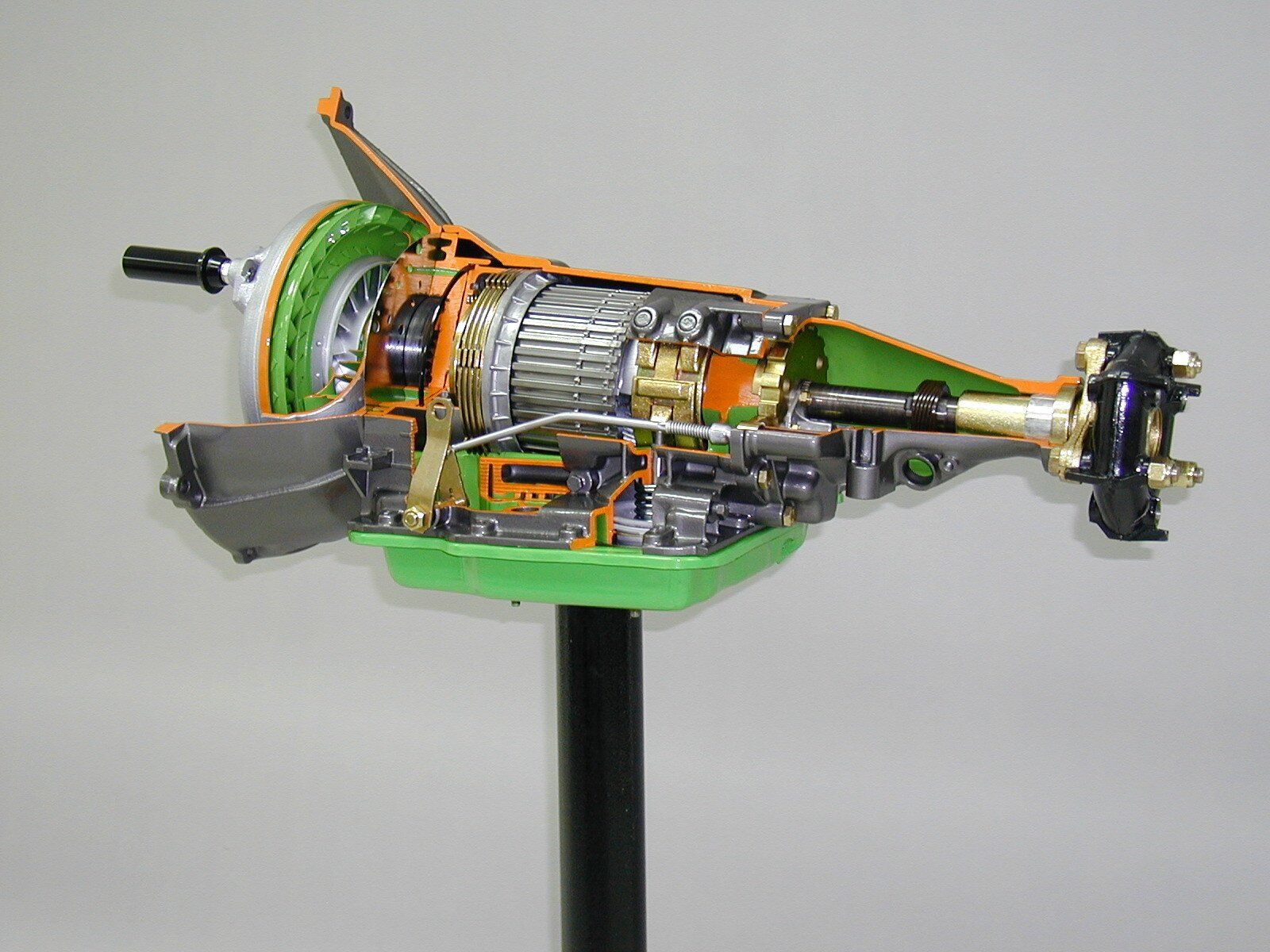

The torque converter is a type of fluid coupling that connects the two main components, the engine and the transmission. An easy way to describe this is by placing two fans facing each other. Turn on one fan at low speed and leave the other turned off. After a few seconds the fan that is turned off will start to spin. Turn the running fan on high and the second fan will pick up speed matching the wind velocity of the first. A torque converter does this except with transmission fluid. As the engine runs, it turns a set of blades, or impellers, inside the torque converter. A second set of blades, called the Turbine, attached to the transmission, is driven by the first without ever actually coming into contact. The system uses only liquid to drive the transmission from the engine. A torque converter differs from a standard fluid coupling in that it provides a variable amount of torque depending on driving needs and engine speeds.

In my search for education on the matter, I found a video on fluid coupling. It was made by the U.S. Army in 1953 and is the best video regarding fluid coupling I have ever seen. This video is for education and has a Creative Commons Attribution license, so you can show this in your classroom.