Precision cooling isn’t limited to internal combustion engines. Battery electric vehicle cooling may be even more complex, as high-rate battery pack charging comes into use, but for the present, let’s look at GM’s new cooling system for the 2.7-liter four-cylinder, and how different it will be to service.

The system doesn’t have a thermostat, so if you sud- denly are thinking, “Hey, that’s the part I’ve replaced most in cooling system service over the years, followed by radiator, hoses, belt and water pump.”Well, relax. It has lots of parts.

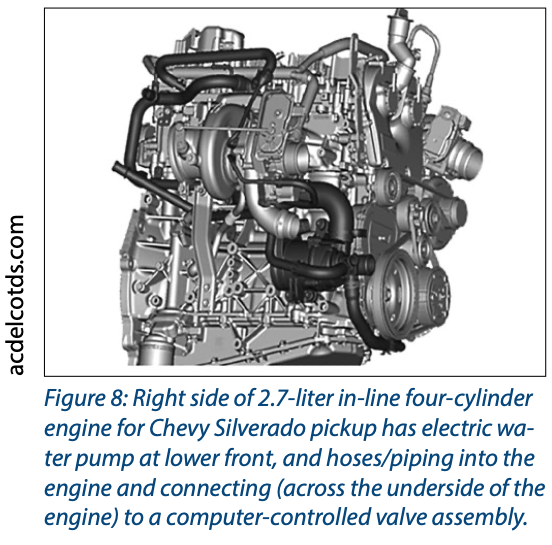

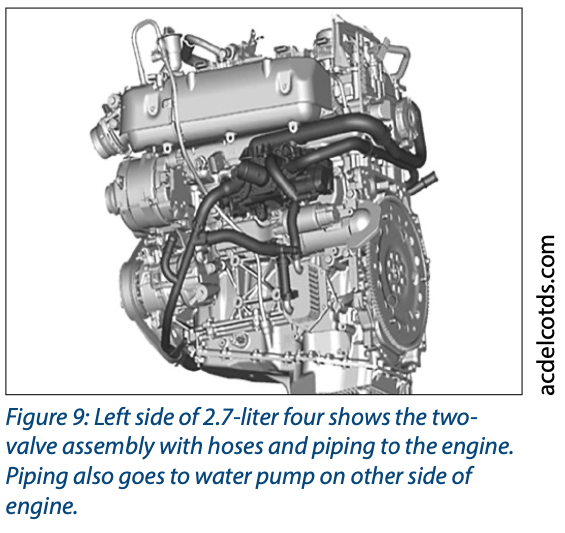

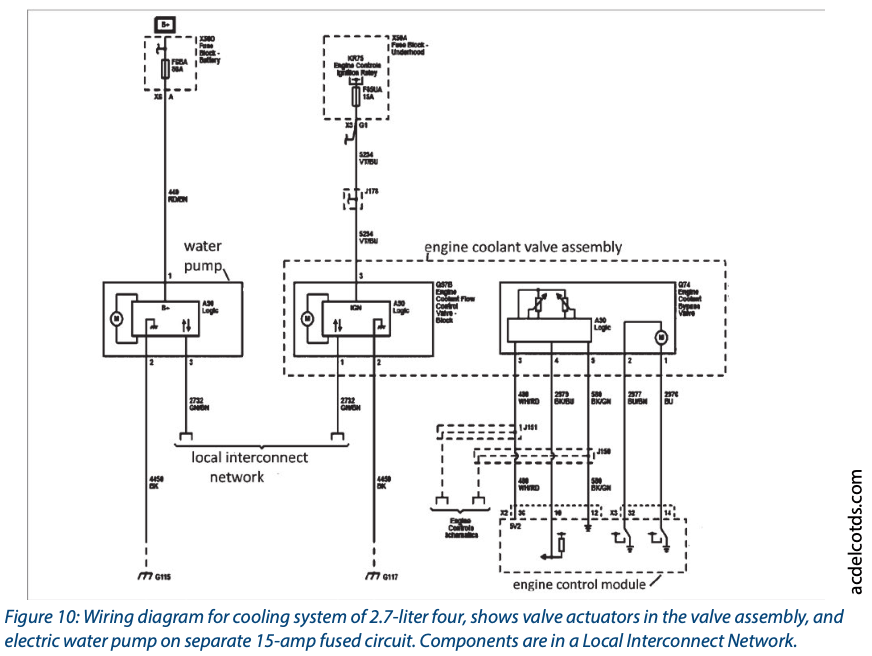

There’s an electric water pump on the right side of the engine. And as the illustrations show (Figures 8 and 9), there’s a lot of external hoses and piping, but the pump itself, as an electric motor-driven device, does not have a belt wrapped around it. Although the water pump’s electrical control (by the engine computer) means it’s infinitely variable and perhaps more subject to failure, it’s also more accessible for service than the integrated mechanical pumps on some conventional engines. And although the thermostat may be gone, there’s a massive coolant control valve on the left side of the engine (which is actually a combination of two valves).

One valve section is integrated with a hot coolant manifold, which controls the flow to the radiator, a bypass circuit, and engine oil and transmission oil heating or cooling circuits, using one actuator. It’s this valve that not only regulates engine warmup, but is a primary factor in eliminating the need for the thermostat.